Unit 4-1-2-5, Lianhua Street 11, Hi-Tech Zone, Zhengzhou, Henan, China

Unit 4-1-2-5, Lianhua Street 11, Hi-Tech Zone, Zhengzhou, Henan, China

info@etangoiltool.com

info@etangoiltool.com

+86-155 1595 8525

+86-155 1595 8525

Non-magnetic steel is a kind of steel functional material, that is, a low-magnetic steel material that basically does not produce magnetic induction under the action of a magnetic field.

The room temperature structure of non-magnetic steel requires a stable austenite metallographic structure: precipitation hardened austenitic stainless steel.

This is because ferrite, pearlite and martensite structures are ferromagnetic at room temperature, and show strong magnetization in a magnetic field, and have high magnetic permeability. Austenite with a face-centered cubic structure is paramagnetic and has a very low magnetic permeability. By appropriately adding alloying elements to expand the austenite zone in the Fe-℃ alloy phase diagram and heat treatment methods (1060℃ solution treatment, quenching) 450-550℃ low-temperature forging, a stable single-phase austenite structure can be obtained at room temperature, thereby keeping the magnetic permeability of the steel material at a low level.

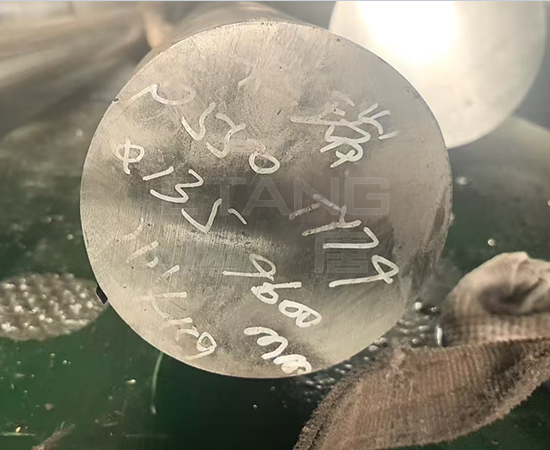

P530 is usually used in the coal gas layer industry to produce non-magnetic probes, drill pipes, spiral drill pipes, etc. In the oil and gas field industry, it is usually used to produce non-magnetic drill collars, non-magnetic heavy weight drill pipes, non-magnetic flow coupling, non-magnetic while drilling measurement instrument housings, non-magnetic flanges, etc.

| C | Si | Mn | P | S | Cr | Ni | Mo | N | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | P530 | . | . | 18.50 | . | . | 13.00 | . | 0.40 | 0.25 | Mn+2Ni≥19% |

| Max. | 0.05 | 1.00 | 20.00 | 0.03 | 0.02 | 14.00 | 2.00 | 0.60 | 0.40 | ||

| Min. | P550 | . | . | 20.50 | . | . | 18.30 | 1.40 | 0.50 | 0.60 | Mn+2Ni≥22% |

| Max. | 0.06 | 1.00 | 21.60 | 0.03 | 0.02 | 20.00 | . | 0.80 | . | ||

| Min. | P650 | . | . | 19.50 | . | . | 18.00 | 3.00 | 1.70 | 0.55 | Cr+3.3Mo+16N≥35% |

| Max. | 0.06 | 0.80 | 20.50 | 0.025 | 0.01 | 19.00 | 4.50 | 2.00 | 0.65 |

| Yield Strength | Tensile Strength | Elongation (%) | Hardness (HB) | Impact Charpy-V (J) | |

|---|---|---|---|---|---|

| P530 | ≥100Ksi (690Mpa) | ≥120Ksi (830Mpa) | ≥25 | 260-350 | ≥122 |

| P550 | ≥130Ksi (900Mpa) | ≥150Ksi (1035Mpa) | ≥20 | 350-430 | ≥82 |

| P650 | ≥170Ksi (1173Mpa) | ≥185Ksi (1277Mpa) | ≥12 | 330-450 | ≥110 |