Drill collar is one of ETANG's main products. With high-quality 4145H/4145H-Mod/Non-magnetic alloy raw materials and excellent machining capabilities, ETANG drill collars are widely used in oilfield drilling equipment around the world.

| Reference Standards | API SPEC 7-1, SY/T5144 |

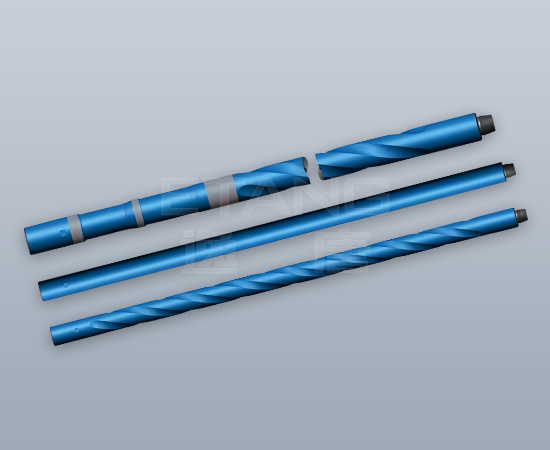

| Drill Collar Type | Standard drill collar/Spiral drill collar |

| Brinell hardness range | 285-341 HBW |

| Material | AISI 4145H/AISI 4145H-Mod/Non-magnetic Alloy |

| Minimum average Charpy impact value | 40 ft-lbs |

Spiral Groove:

To reduce the pressure difference, the surface of the drill collar can be spiral. Compared with the smooth standard drill collar, the weight loss of the spiral drill collar is about 4%.

Stress Dispersion Groove & Bore Back Box:

The stress dispersion groove improves the bending strength of the pin and box connection, thereby improving its durability.

The Bore Back Box achieves a gradual reduction in the internal diameter by gradually increasing the cross-sectional area of the material at critical section. Therefore, under the action of static/dynamic loads, the stress concentration phenomenon is greatly alleviated, and the failure frequency is greatly reduced.

Hardbanding:

ETANG provides the following wear-resistant materials: Arnco-100xT, Arnco-300xT, TCS-8000;

Slip and elevator recess:

Slip and elevator recess improve downhole processing efficiency and safety, and ETANG processes them according to API 7-1.

Unit 4-1-2-5, Lianhua Street 11, Hi-Tech Zone, Zhengzhou, Henan, China

Unit 4-1-2-5, Lianhua Street 11, Hi-Tech Zone, Zhengzhou, Henan, China